The world doesn’t buy brand-name drugs anymore-it buys generics. And most of them come from Asia. India and China together make up more than half of the global supply of affordable medicines, from antibiotics to cancer treatments. But they’re not the same. India is the volume king, shipping out pills by the billions. China controls the raw ingredients that make those pills possible. And countries like Vietnam and Cambodia are quietly slipping into the gaps, building niche businesses that bigger players overlook.

India: The Pharmacy of the World

India’s rise wasn’t luck. It was policy. In the 1970s, the government changed its patent laws to allow companies to copy drug formulas as long as they used a different manufacturing process. That opened the floodgates. Suddenly, Indian firms could make life-saving medicines at a fraction of the cost. Today, India supplies over 60% of the world’s vaccines and 40% of the generic drugs sold in the U.S. That’s not a small number-it’s the backbone of global access to medicine.

The numbers speak for themselves. In 2024, India’s pharmaceutical market hit $61.36 billion, with 75% of that coming from conventional generics. Gujarat and Maharashtra are the powerhouses, accounting for over 60% of production. There are more than 3,000 manufacturing sites approved by the U.S. FDA-more than any other country. But here’s the catch: only 15% of those can handle advanced biologics. Most still churn out simple pills and capsules.

What keeps India ahead? Speed and service. If you need a custom formulation, Indian manufacturers can deliver in two weeks. Chinese suppliers? Expect 30 to 45 days. U.S. pharmacy chains say Indian customer support is 24/7-no time zone barriers, no language issues. That’s why 68% of major American drug distributors now source 40-60% of their generics from India. They’re not just buying cheaper drugs-they’re buying reliability.

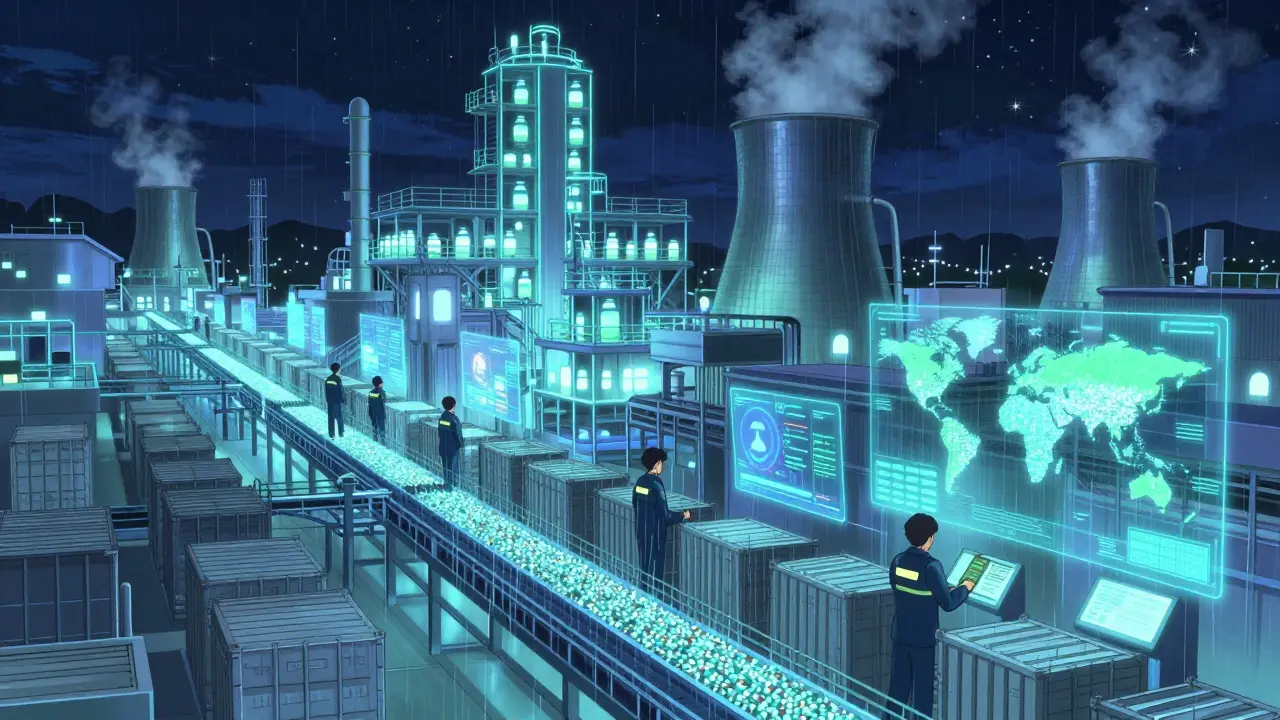

China: The Hidden Power Behind the Pills

China doesn’t sell you the pill. It sells you the powder inside it. The country controls 70% of the global market for Active Pharmaceutical Ingredients (APIs)-the chemical building blocks of every medicine. Without China’s APIs, India can’t make its generics. And yet, India still imports 68% of its API needs from China, despite spending billions trying to become self-sufficient.

China’s market is bigger-$80.4 billion in 2024-but it’s not just about volume. It’s about value. While India makes low-cost pills, China is moving up the chain. Forty-five percent of new manufacturing plants built between 2020 and 2024 were for biologics-complex, high-value drugs like cancer treatments and insulin. China’s 14th Five-Year Plan poured $150 billion into biologics R&D. That’s not a bet-it’s a takeover strategy.

Quality control is the elephant in the room. In 2024, the U.S. FDA issued 142 warning letters to Chinese manufacturers-almost twice as many as India’s 87. That’s why big buyers now use dual-sourcing: get 40% from India, 30% from China, and keep the rest in reserve. One German healthcare company told us their supply chain costs jumped 18% after they had to double-check every batch from China. But here’s the flip side: Chinese APIs are still 20% cheaper than Indian ones. For bulk buyers, that’s hard to ignore.

The Emerging Players: Vietnam, Cambodia, and the Niche Game

While India and China fight over the big contracts, smaller countries are carving out their own space. Vietnam’s pharmaceutical exports jumped 24.7% in 2024 to $2.8 billion. How? They focused on one thing: antibiotic intermediates. They don’t make the final drug. They make the key chemical step that goes into it. It’s a small piece of the puzzle-but it’s one that’s hard to replace.

Cambodia? They’re not making pills. They’re assembling medical devices. From syringes to blood pressure cuffs, their assembly sector grew 32% last year. Why? ASEAN trade deals give them tax breaks and duty-free access to regional markets. It’s not glamorous, but it’s profitable. And it’s growing faster than either India or China in their specific niches.

These countries aren’t trying to beat the giants. They’re learning how to work with them. A Vietnamese firm might supply intermediates to an Indian manufacturer. A Cambodian factory might pack devices for a Chinese distributor. It’s a new kind of supply chain-one that’s less about dominance and more about interdependence.

Who Wins When the World Needs Medicine?

India and China aren’t rivals-they’re partners in a broken system. India needs China’s APIs. China needs India’s distribution network. The U.S. and Europe need both. But the cracks are showing.

India’s plan to cut API imports from 68% to 30% by 2030 sounds good. But building 12 new API parks takes time, money, and stable power grids. Right now, India’s infrastructure adds 12-15% to logistics costs. China’s centralized system doesn’t have that problem.

China’s push into biologics is smart. But it’s expensive. And if the U.S. FDA keeps tightening rules-like its new Project BioSecure requiring full traceability of every API batch-compliance costs could rise 18-22%. That’s a threat to low-margin players on both sides.

Meanwhile, the WHO reported a 27% increase in inspection failures at Asian facilities in 2024. Quality isn’t just a buzzword-it’s the only thing that keeps the whole system from collapsing.

What This Means for You

If you’re a patient, you’re probably not thinking about where your pills come from. But you should. The next time you refill a prescription for metformin, amoxicillin, or insulin, know this: it likely came from a factory in Gujarat or Jiangsu. And if geopolitical tensions, trade wars, or a natural disaster disrupt supply chains, you’ll feel it in your wallet-or your health.

For businesses, the lesson is clear: diversify. Relying on one country for your supply is a gamble. The best companies now source from both India and China, plus a backup from Vietnam or Thailand. They don’t just look at price. They look at lead time, communication, and regulatory history.

For policymakers, the challenge is bigger. Self-sufficiency sounds noble. But making your own APIs isn’t just about building factories. It’s about building a whole ecosystem-skilled workers, reliable energy, strict quality control, and international trust. India and China are trying. But they’re still far from perfect.

The Future Isn’t Just About Cost

The next decade won’t be won by the cheapest producer. It’ll be won by the most reliable one. India has the speed, the service, and the volume. China has the scale, the innovation, and the raw materials. But neither can do it alone.

By 2030, India’s market could hit $130 billion. China’s might reach $126.6 billion. But the real story isn’t in the numbers. It’s in the shift: from cheap pills to smart, traceable, high-quality medicines. The world doesn’t just want affordable drugs. It wants safe ones. And that’s a race neither country can afford to lose.

It's wild how we take medicine for granted. Like, I just swallow a pill and never think about who made it or what chemical trail it took to get here. But this post? It hits different. India and China aren't just factories-they're the invisible backbone of global health. And we're all just beneficiaries, barely paying attention until something breaks.

My cousin works in pharma logistics and she says Indian reps are the only ones who text you back at 2am. No joke. China gives you the cheapest stuff but good luck getting a human on the phone. India? They treat you like a partner, not a number. That’s why I’ll always pick them when I can.

China is stealing our medicine supply and no one’s talking about it. They control 70% of APIs and they’re not even trying to hide it. India’s trying to break free but they’re still begging for Chinese powder like it’s oxygen. This isn’t trade-it’s colonization with pills.

Why is everyone so obsessed with cost when quality keeps failing inspections 27 percent more last year I mean like how is that not the real story here

India’s 60% vaccine share looks impressive until you realize 85% of their output is low-margin generics. China’s investing $150B in biologics while India still runs on 1980s tech. The real winner? The WHO. They’re just watching the whole system collapse slowly

As someone who grew up in both countries, I’ve seen how this works. In rural India, people get insulin from Mumbai-made generics. In rural China, they get the API that makes it. Neither country owns the whole chain. But they both know the other’s weakness. That’s not competition-it’s survival.

Let’s stop acting like this is a zero-sum game. India gives us speed and trust. China gives us scale and innovation. Vietnam and Cambodia? They’re the quiet heroes making sure the gears don’t seize. The future isn’t about who wins-it’s about who works together best. And honestly? That’s already happening.

OMG I just realized-I’ve been taking metformin for 10 years and I have NO IDEA if it came from Gujarat or Jiangsu… that’s terrifying… and also kind of beautiful? Like, our lives are literally held together by invisible global teamwork. Can we just… thank these people??

It is imperative to note that the U.S. FDA's issuance of 142 warning letters to Chinese manufacturers in 2024 constitutes a statistically significant deviation from the 87 issued to Indian manufacturers, suggesting a systemic divergence in regulatory compliance. Furthermore, the projected 18-22% increase in compliance costs for Chinese firms under Project BioSecure may induce material supply chain restructuring.

You think this is about medicine? Nah. It’s about power. Whoever controls the chemicals controls the body. India thinks it’s the pharmacy of the world. But without China’s powder, it’s just a pharmacy with empty shelves. And we? We’re the patients waiting for the next miracle pill that might not come

It’s fascinating how Vietnam and Cambodia are succeeding not by competing, but by complementing. They’re not trying to replace giants-they’re becoming the essential connectors. That’s smart, sustainable growth. And honestly? It’s the model the West should be copying, not just demanding cheaper pills.

Wait so if India needs Chinese APIs and China needs Indian distribution… who’s actually in charge here? Is this just one giant global puzzle where everyone’s holding one piece and pretending they’re not all just one bad shipment away from chaos

India’s infrastructure adds 12-15% to logistics? That’s pathetic. China’s got high-speed rail, AI factories, and state-backed R&D. India’s still stuck with power cuts and port delays. Stop romanticizing them. They’re not heroes-they’re just the last option before everything collapses.

Everyone’s talking about pills and APIs but no one mentions the workers. The people in Gujarat factories working 16-hour shifts. The chemists in Jiangsu who never get credit. This isn’t just economics-it’s human labor on a global scale. And we’re all just scrolling past it.